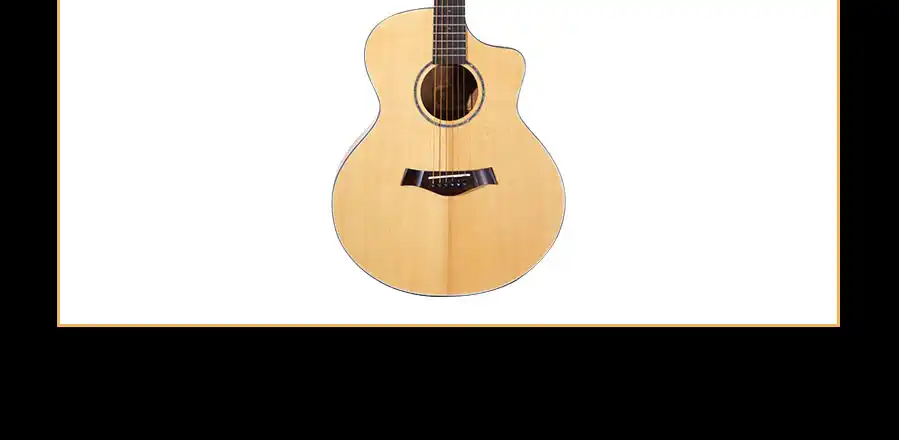

40 inch matte acoustic guitar listings work best in B2B when the product can be explained clearly, reordered reliably, and photographed consistently across batches. This model is designed as an intermediate-tier option for dealer networks, distributor assortments, and importer catalogs that need a stable “middle ladder” guitar—strong enough to justify an upgrade, but structured for repeatable wholesale supply rather than one-off showroom pieces. In real bulk operations, the value of a guitar is not only tone; it is how predictably the next shipment matches the first product page your customers have already approved.

The concept is practical: a responsive spruce top supports clear articulation and a quick, clean attack that buyers can describe without exaggeration. The body is specified with a mahogany core plywood structure to help maintain consistency and reduce unnecessary variation in large orders. For many B2B buyers, that consistency is more valuable than chasing unstable “boutique” promises, because it protects your SKU discipline, reduces returns, and keeps marketing assets (photos, videos, and spec tables) aligned over time.

To keep your category ladder clean on your store, position this model naturally inside your Intermediate Guitars collection. A clear ladder reduces friction: buyers can see where the model sits, understand the upgrade logic, and compare it against neighboring SKUs with less confusion. This is the same reason professional procurement teams prefer stable intermediate lines—they can standardize training programs, store displays, and online listings with fewer internal errors.

For neutral, non-salesy education about what a guitar is and how it sits in the instrument family, you can reference a broad, widely recognized source like Encyclopaedia Britannica. Then keep your product page focused on what matters operationally: consistent specification, predictable ordering, and export-ready workflow that supports repeat business.

40 inch matte acoustic guitar buyers often evaluate the spec story in two directions at once: “How does it sound and feel?” and “How will it behave in bulk supply?” This model’s material structure is built to answer both. The spruce top provides fast response and a bright, defined attack—useful for intermediate players who want notes to speak clearly during practice, ensemble work, and studio environments. Spruce is commonly chosen for its responsive character, which helps the guitar remain articulate across a range of dynamics.

The back and sides use a mahogany core plywood structure. In B2B purchasing, plywood is not only a cost decision; it is a consistency decision. It can help reduce unpredictable variation and supports a stable outward look for catalog photography and retail display. If your buyers need a basic, authoritative reference on wood as a material and why species properties matter in manufacturing, a technical anchor like the USDA Forest Products Laboratory publications can serve as background reading. Your listing can remain practical: a stable tonewood narrative that does not rely on fragile claims.

The matte natural-wood finish is also a B2B-friendly choice. Matte finishes can be easier to present as “workhorse” instruments for programs and resellers, and they often photograph in a clean, honest way without demanding dramatic lighting tricks. For bulk channels, this matters: consistent visuals reduce misunderstandings and improve cross-border communication, especially when multiple stakeholders—procurement, QC, marketing, and sales—must agree on what “the same model” means.

In short: spruce supports clarity and response, mahogany-core plywood supports stable bulk consistency, and matte finishing supports practical merchandising. This combination is designed for intermediate catalogs where the buyer needs confidence, not speculation.

40 inch matte acoustic guitar program success depends on predictable playing feel. Many bulk buyers are serving schools, training studios, and multi-store dealer chains where the guitar must feel consistent across units. This model emphasizes clear specification at the main contact points: a rosewood fingerboard supports a familiar playing surface with a stable, comfortable feel, and a hardwood bridge (redwood) completes the core setup interface where string energy transfers into the top. When buyers manage multiple SKUs, these clear material callouts reduce confusion and help sales teams explain “why this model sits at intermediate level” without overpromising.

String choice is standardized with ALICE strings, supporting a consistent out-of-box presentation across shipments. In B2B, a stable string specification is useful because it reduces “uneven first impression” issues—especially when products are displayed on walls, sampled in showrooms, or checked quickly by receiving teams. A predictable baseline makes it easier for dealers to run consistent demos and for importers to standardize inbound inspection checklists.

If your market sells bundles or add-on kits, keep the core instrument stable and tailor only the accessory layer. You can build channel-specific kits through Accessories without changing the main guitar specification. This approach is operationally strong: it protects SKU discipline, reduces internal errors, and allows different buyer segments to choose their preferred “package logic” (extra picks, straps, bags, spare strings, or protective items) while the core listing remains consistent across regions.

For intermediate buyers, the goal is not to claim perfection—it is to deliver a repeatable playing experience and a spec sheet that stays accurate over time. This is the kind of clarity that supports wholesale growth.

40 inch matte acoustic guitar supply becomes scalable when buyers trust reorder consistency. In intermediate segments, many customers do not want surprises: changes in appearance, setup feel, or packaging can create cost in returns, customer service, and rating volatility. That is why this model is positioned with two operational priorities—QC alignment and controlled customization—so the product page can remain credible as order volume increases.

For inspection alignment, connect buyers to a shared, documented process using your factory’s QC workflow. A shared checklist reduces ambiguity between factories, importers, and dealer receiving teams. Practical checkpoints often include finish consistency (matte uniformity), neck straightness, fret ends and fingerboard surface, basic setup targets, and visual consistency in top grain and body color. The objective is not to promise that every unit is identical in a handmade sense; it is to keep variation within an acceptable window so the model stays aligned with the listing.

For private label needs—logo placement, carton marks, barcode mapping, or standardized manuals—route changes through controlled OEM/ODM services. This prevents “spec drift” that silently breaks your product page over time. The best wholesale practice is simple: keep the core guitar specification stable, and handle branding or packaging variations through a defined workflow. This protects the dealer’s reputation and the importer’s internal operations, because future shipments remain aligned with the original product photography and sales copy.

In intermediate B2B channels, consistency is a competitive advantage. QC alignment and OEM control are what turn a good-looking model into a reorder-friendly SKU.

40 inch matte acoustic guitar decisions are ultimately judged by landed reliability. This model is intended to support export-ready packing expectations and can be planned within a 7–15 day delivery window for ready-stock configurations, depending on quantity, packing schedule, and destination coordination. In B2B, the buyer’s real pain is not only product quality—it is avoidable damage, unclear packing standards, and time lost in rework. That is why packaging discipline is part of the product value.

For logistics transparency and packing expectations, route buyers to Shipping/Delivery/Packaging so they understand protection methods and coordination steps. When wood packaging compliance is relevant, a recognized reference is the IPPC ISPM standards. Early alignment reduces delays and helps avoid costly corrections at ports or warehouses, especially when shipments move through multiple handlers.

Q: who is this model designed for?

A: it is designed for dealers, distributors, and importer programs that need an intermediate 40-inch matte acoustic guitar with repeatable wholesale supply.

Q: what is the key material story?

A: a responsive spruce top paired with a mahogany core plywood body, built to support stable bulk consistency and clear listing communication.

Q: can we customize branding or cartons?

A: yes. private label and packaging marks can be standardized through the OEM/ODM workflow while keeping the core specification stable.

Q: how should we align receiving inspection?

A: use a shared checklist through the QC process so finish, setup targets, and visual consistency are evaluated the same way on every shipment.

Q: what delivery window should we plan for?

A: planning is commonly 7–15 days for ready-stock configurations, depending on quantity and shipping arrangements.